In the previous three Parts, we shared the OSHA requirements when using portable generators in the workplace and how to determine or test to see if your generators are compliant.

Now, in Part 4 we’ll transition to the reasons why a lack of neutral bonding can contribute to electrical hazards and an increased risk to workers when using portable generators with floating neutrals.

Additionally, we will discuss other safety hazards and some mitigation tips, both electrically and non-electrically related, when using portable generators.

What is the Potential Harm to Electrical Workers?

There are two main reasons why proper neutral bonding is related to employee safety for protection against electric shock.

Compromise the GFCIs and OCPDs

First, a portable generator with a floating neutral could compromise the proper operation of GFCIs and OCPDs to the point where they may not operate as designed, thus significantly increasing the risk of electric shock to employees.

Creation of Touch Potential

Secondly, if the ‘hot’ ungrounded conductor contacts the frame of the generator with a floating neutral, all the metal parts will become energized at that electrical potential, including the frame of the vehicle if the generator is mounted to a vehicle. The subsequent ground fault would keep the generator frame energized at hazardous voltages rather than tripping the OCPD and deenergizing the circuit as would occur with a generator with its neutral bonded to the frame.

With the frame of the generator and/or frame of the vehicle energized, there will be a difference of electrical potential between them and the worker who inadvertently touches it. Current only flows when there are differences in electric potential.

Are Floating Neutrals (Ungrounded Systems) Safer?

Some individuals have attempted to argue that an ungrounded system, i.e. floating neutral, is inherently safer than a grounded system because there is no electrical reference to ground. While this may be somewhat true, it only applies to permanently installed ungrounded systems designed and engineered for specific operational needs.

For example, some processing facilities use an ungrounded delta system to provide critical circuits that need a high continuity of operation for systems that can’t be immediately shut down following a single-phase fault to ground fault. The unexpected shutdown of the operations of the equipment could cause damage to both the equipment and/or the product being processed.

In other places, such as nuclear power plants, ungrounded circuits are designed to provide electrical power to critical motor operated valves (MOV) and other important safety related equipment needed for use during emergencies to protect the reactor.

In all such cases, whether the equipment is ac or dc, ungrounded systems are deliberately limited to only very specific needs and for certain key equipment.

Requirements for Ungrounded Systems

Regardless of the reasons for using ungrounded systems, the other important safety fact some individuals miss is that all ungrounded systems are required to have an active ground-fault detection system installed that continuously monitors for ground faults. Most are so sensitive they can detect either a ‘hard ground,’ meaning one phase directly faults to ground with many amps flowing, or a ‘soft ground,’ where milli-amps of current leak to ground due to dampness or other factors that reduce the insulation value.

And it is for this safety reason the National Electrical Code® (NEC®) 250.21(B) mandates the installation of ground-fault detection systems for ungrounded ac systems and 250.157(A) for ungrounded dc systems. If a ground fault occurs, the ground detection system annunciates an audible and/or visible alarm to warn personnel of the dangerous condition so the equipment can be safely powered down to repair the equipment before a second phase faults to ground, which would result in a phase-to-phase short circuit through ground.

No Good for Portable Generators

When using portable generators with floating neutrals, there is no ground fault monitoring system in place to warn employees if a ground fault exists; consequently, the worker is totally unaware of the extremely dangerous condition. Therefore, the argument that ungrounded systems are safer than grounded ones is a moot point when speaking in context of portable generators.

Separately Derived System

Some of you may be wondering , “Why then are portable generators with floating neutrals available?”

To answer the question, we will need to temporarily move away from the main topic to a secondary related one.

Let’s return to the term and definition of a separately derived system, from Part 1, which is defined as “A premises wiring system whose power is derived from a battery, a solar photovoltaic system, or from a generator, transformer, or converter windings, and that has no direct electrical connection, including a solidly connected grounded circuit conductor, to supply conductors originating in another system.” The key words from the definition are “that has no direct electrical connection.”

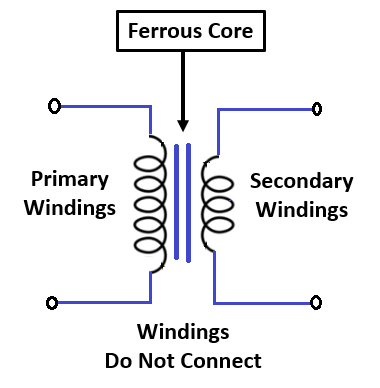

Two excellent examples of separately derived systems would not only include generators but also the utility transformer providing power to your home. They both have two or more sets of windings, which are not physically connected to one another, as shown by Figure 10.

The windings are essentially coils of insulated wires wrapped around an iron “ferrous” core that develop a oscillating magnetic field when energized. The two sets of windings – for example, the primary and secondary in a transformer – are in very close proximity to one another but do not actually touch, otherwise a short circuit would occur. Voltage and current are transferred from one winding to the other through mutual electromagnetic induction rather than a direct electrical connection, such as copper terminations.

To connect a generator to your home or another structure with a utility service requires the use of a transfer switch to isolate the utility system from the generator. If a generator is connected to a home or business without a transfer switch, then electrical current can back feed into the utility grid if the main circuit breaker is closed. This poses significant electric shock hazards to utility line workers. Generators back feeding the distribution grid have seriously injured and killed utility workers.

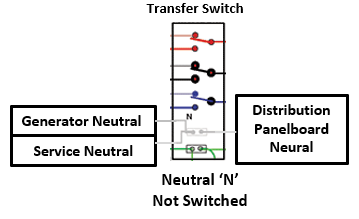

Transfer switches come in a variety of types and functions, such as automatic or manually operated models, but they can all be reduced to two basic configurations: those that switch only the “hot” ungrounded conductors and those that switch both the “hot” ungrounded and the neutral/grounded conductor.

Generators with floating neutrals are required to be used with transfer switches that switch only the “hot” ungrounded conductors (red, black and blue), as shown in Figure 11. This is because the system neutral inside the service panel is already bonded to the grounding electrode through the main bonding jumper (MBJ).

The generator’s neutral winding will be electrically connected to the system ground through the hard connection inside the transfer switch. In this case, the generator would not qualify as a separately derived system because of the direct connection of its neutral to the system ground through the transfer switch.

If a generator with the neutral bonded to frame is used, then there would be two neutral bonding points in the overall circuit, one in the transfer switch which is connected to the service neutral and the second in the generator which is not permitted.

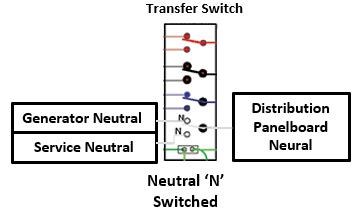

However, if the transfer switch opens and closes both the “hot” ungrounded conductors (red, black and blue) and the neutral/grounded conductors during manipulation, as shown by Figure 12, then a generator with a neutral bonded to the frame which is also grounded is needed because the transfer switch completely isolates all connections, including the neutral, from the utility service.

If a generator with a floating neutral is used with this type of transfer switch, then the circuit from the generator to the distribution panel would be an ungrounded system which is not permitted without a ground fault detection system. In this second case the generator would be a separately derived system because no direct connection exists between it and the service panel.

I understand the topic of transfer switches and service panels is slightly outside of our main subject of grounding portable generators, but I felt a short explanation was warranted for those who are wondering why floating neutral generators are offered for sale.

Safety Tips

However, many other dangerous hazards are associated with the misuse of portable generators that can and has injured and killed workers which needs be briefly addressed with the following safety tips:

- Always have GFCI protection when using electrical power from portable generators.

- Don’t use portable generators during rain storms or in other wet conditions.

- Never operate portable generators inside buildings, structures or other enclosed areas, even with doors and windows open because they can produce deadly levels of carbon monoxide very quickly.

- Never operate portable generators near open windows, doors, operating HVAC units or other ventilation equipment. Many safety organizations recommend a minimum of 25 feet distance.

- Turn off all load devices before turning on or shutting the generator down.

- Don’t overload the generator’s power wattage capacity.

- Maintain adequate distance from combustible materials, tall grass, dry vegetation, or flammable liquids.

- Ensure the portable generator is set on a firm level surface.

- Never add fuel to the generator while the engine is running or is still too hot to touch.

Conclusion

Grounding of portable generators is not as simple as driving a ground rod and connecting our portable generators to it. As we have learned, correct grounding (“bonding” would be the better word) of portable generators according to OSHA regulations is much more complex and requires technical understanding of the “how’s” and “why’s.” But once the concept is grasped, then it makes sense.

Portable generators are wonderful tools that offer us so many benefits and flexibility to complete our jobs efficiently when permanent power is not available. But that is just one side of the portable generator coin. Contained within these advantages is the other side of the coin, which poses dangers and hazards if we do not use generators correctly by following all the safety rules and regulations.