Is Your Generator OSHA Compliant?

Previously in Part 2, we explained the OSHA directives for grounding portable generators and when it’s mandatory in the workplace.

In Part 3, we will focus on some of the ways to determine if the generator(s) you currently own or are considering for purchase are OSHA compliant, i.e., legal for use in the workplace.

Look for a Label

Probably the easiest method to determine if the generator is OSHA compliant is to look for a label somewhere on the generator and/or in the instruction manual for information that essentially reads “NEUTRAL BONDED TO FRAME,” as shown in Figure 3. This information communicates it was built to adhere with the OSHA specifications.

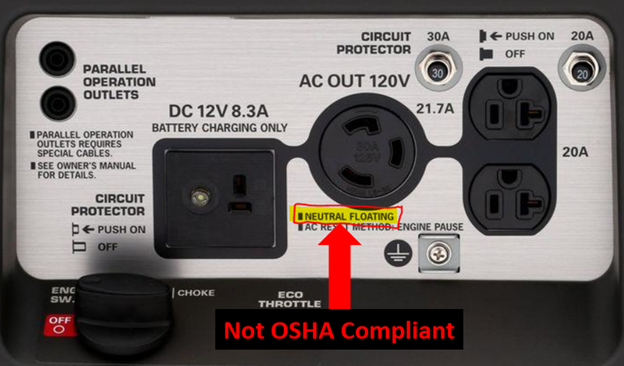

However, if the labeling states something to the effect of “NEUTRAL FLOATING,” as shown in Figure 4, then this would be a concern because it would not comply with OSHA. But be aware, while I’ve never personally found a generator labeled ‘Neutral Bonded to Frame’ that wasn’t, I’ve been informed by others that they have stumbled across them.

The affected generators were low cost off-brands built in countries with very little or no safety regulations and were purchased online from questionable sources. However, if you procure high quality generators manufactured by recognized name brands from reputable retailers, then this should not be a concern.

Have a Qualified Person Test It

The other method is to test the generator through one of two ways, but it must be performed by a person who is qualified to use the test instrument and is a qualified electrical worker (QEW).

First Test Method

The first and safest way is through a continuity check with the generator off, meaning the engine is NOT running. A generator with its neutral bonded to the frame will have continuity across the outlet’s neutral slot to the equipment grounding conductor (EGC) with a resistance reading substantially less than one ohm.

An additional continuity check must be performed across the EGC at the outlet and at various parts of the metallic frame of the generator to verify these points are also adequately bonded together. Once again, a good, bonded connection(s) will result in an ohmic reading of far below one ohm.

If the digital multimeter (DMM) shows an open circuit across the neutral at the outlet and the EGC, then it has a floating neutral. Furthermore, if there is an open circuit across the EGC and the generator’s metal frame, then this, too, is a safety issue because those two points are not bonded together as required. In either case, the generator does not comply with OSHA regulations and must not be used until corrected by a person who is qualified to make such repairs.

Second Test Method

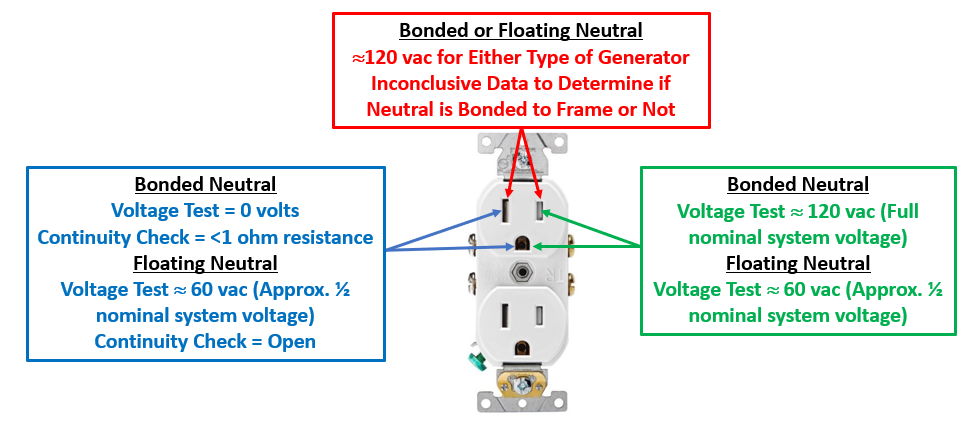

The second method is inherently more hazardous because the generator will be running with dangerous voltages present. A generator with its neutral bonded to the frame will have near zero volts when tested across the outlet’s neutral slot and the EGC. Likewise, a voltage check from the outlet’s EGC to any metallic part of the generator’s frame will also indicate a near zero reading on the DMM. This is because all the points tested will be at the same electrical potential (equipotential) from solidly bonded connections.

However, a generator with a floating neutral will show a voltage (normally around half the nominal system voltage of approximately 60V ac for a single-phase 120/240 volt generator) across the outlet’s neutral and its EGC. The other 60 volts will be located when checking across the outlet’s EGC and the ungrounded “hot.” A floating neutral generator will have a difference of electrical potential between these points.

If a voltage test is performed across from the “hot” ungrounded conductor to the neutral/grounded conductor of either type of generator, with a floating neutral or with the neutral bonded to the frame, the data will be inconclusive and will not provide any useful information because both generator types will show the full nominal system voltage, which is the expected system voltage as shown by the red text in Figure 5.

Figure 5 has been provided to assist the reader with the approximate values that should be expected when testing a generator for either continuity or voltage.

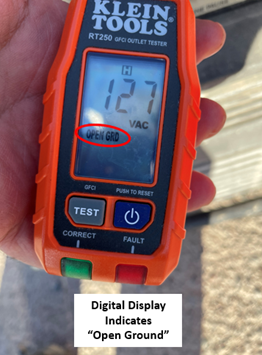

For those without the necessary training and qualification to use DMMs, a portable plug-in outlet tester can be used, either the type with the three indicator lights or the newer models with a digital readout. These simple testing devices are commonly found in many hardware stores at a reasonable price.

If the generator has a floating neutral, then the lights will be in a sequence or the digital display will indicate an “Open Ground,” as shown by Figures 6 and 7 respectively. Also, the models equipped with a button to test the GFCI externally will be very helpful to ensure the GFCI outlets will trip when a simulated ground fault occurs downstream of the outlet.

When the generator’s bonding is properly configured, the outlet tester will indicate a “Correct” wiring configuration, identical to what you would see if testing an outlet in your home that is wired correctly.

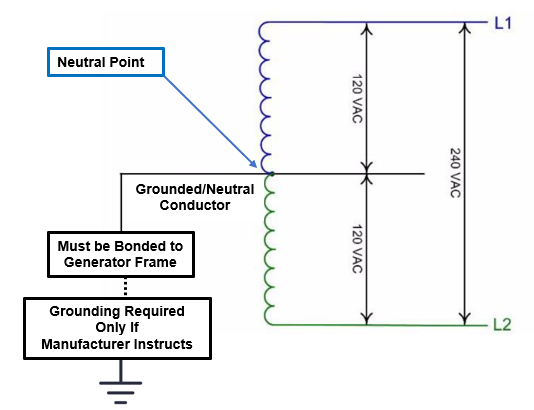

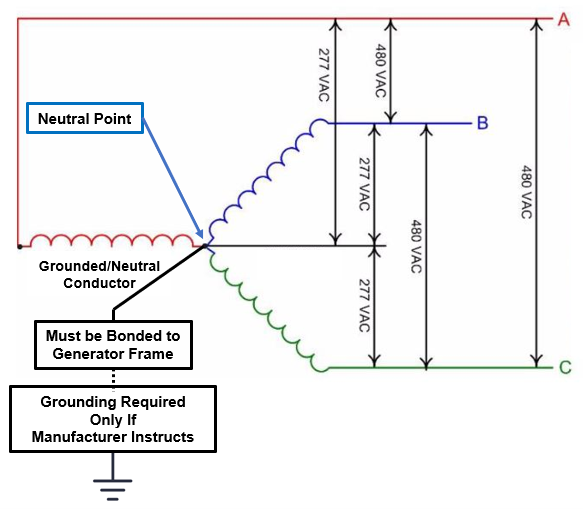

The following two abstract diagrams of typical generators wiring schematics are offered to show the various parts, conductors, and the neutral point in relation to one another.

Figure 8 is the winding diagram of a typical single-phase three-wire 120/240-volt generator. Figure 9 is for a three-phase four-wire 277/480-volt wye connected generator, but it can very easily apply to a 120/208-volt generator.

These schematics should help with a better understanding of the internal dynamics of bonding the neutral point to the generator’s frame. And as previously mentioned in Part 2, connecting the portable generator to ground (earth) is only mandatory if the portable generator is used for purposes outside of the four OSHA conditions or when manufacturer’s instructions dictate grounding. Otherwise, it is optional.

One More Safety Concern

One last safety concern must be pointed out before wrapping up Part 3. There are several makers of commercially available portable plug-in devices commonly called ‘bonding plugs’ or ‘neutral bond plugs.’ They claim to bond the generator’s neutral to its frame, while others have fabricated shop-made devices using a male plug with a short jumper connecting the neutral to the EGC connections.

This may, and we must emphasize MAY, temporarily provide the bonding needs; however, we at e-Hazard strongly recommend against their use for the following reasons:

- These devices have not been independently tested or evaluated by a third party to validate the effectiveness of this function, nor do they carry any kind of safety listing or certification from a Nationally Recognized Testing Laboratory (NRTL) such as UL, CSA, ETL, FM, etc.

- The manufacturers of these devices are companies who make parts and accessories for recreational vehicles and, according to the manufacturers’ information of these ‘bonding plugs,’ they are “designed for Recreational Vehicles” (RVs) using generators with floating neutrals. Not one word is contained in the operating instructions referencing their legal use in the workplace.

- Fabricating a male cord plug configured with a jumper in this manner would violate its “listed and labeled” installation instructions, which is not permitted according to 1910.303(b)(2) or 1926.402(b)(2). This practice could lead to unnecessary additional citations.

- These plug-in devices can be easily unplugged from or partially plugged into the generator through carelessness, which would immediately negate any bonding and return the generator into a non-compliant floating neutral configuration.

- By simply plugging in one of the devices does not guarantee the generator’s neutral is adequately bonded to the frame if the EGC is not also properly connected to the frame, which can’t be determined without additional testing by an electrically qualified person using a DMM every time they’re used.

For the sake of brevity, we only covered five compelling reasons for not using these portable ‘bonding plugs’ in the workplace. Essentially, these unlisted ‘bonding plugs’ are nothing more than a temporary band-aid fix which cannot validate with 100% certainty they will consistently provide the necessary safety conditions established by OSHA.

Therefore, the right thing to do is purchase the correct type of generators that are already preconfigured correctly by the manufacturer to meet all the OSHA regulations, thus ensuring workers are adequately protected whenever they’re used.

Next in Part 4

We will finish our discussion of portable generators in Part 4 by covering the safety hazards and risks when generators are not correctly bonded, in addition to other safety precautions.

Very interesting series of articles.

I would like to ask for your opinion about the safety of “portable power stations” widely available now, based on batteries and inverters, used mainly during camping or home power outages.

I guess they can be defined as single phase “separately derived systems” with “floating neutrals”. Their receptacle outlets have a third hole, which seems to be not connected to any grounding conductor. The “frame” of such portable power stations is usually non-metallic (plastic). Some of them have a grounding bolt that may be or may be not connected to earth… I doubt that any GFCI is internally included.

You bring up an interesting point RI, but one that I’ve not personally dealt with in my workplace. If these ‘Portable Power Packs’ are used in a personal environment such as at homes, camping, etc. then the OSHA regulations would not apply.

However, if they’re used in a workplace then that’s a completely different scenario. It looks like these devices are a fairly recent invention so there are no existing OSHA regulations, either 1910 or 1926, that would specifically address them. I was also unable to find an OSHA Letter of Interpretation related to these portable power stations. However, UL 2743 is a new standard recently developed in 2016 (Updated 4/14/2023 as ANSI/Can/UL 2743) titled “Standard for Safety, Portable Power Packs” to establish some safety criteria for this new product but I haven’t had a chance to review it in detail.

And without testing one of them, I wouldn’t know if their neutral was floating or not.

Obviously I can’t speak officially for OSHA but I believe some of their existing regulations would apply, because like any other source (temporary or permanent) of electric power, it can poses hazards and safety risks to workers.

The most applicable OSHA regulation would be 1910.303(b)(2) and 1926.403(b)(2) which essentially requires “Listed or labeled equipment shall be installed and used in accordance with any instructions included in the listing or labeling.” Since this product has a UL listing, then at a minimum the employer would have to adhere to all the UL specifications and limitations.

But these portable power packs would also fall into the classification as temporary branch circuits, which would bring in the requirements of 1910.304(b)(3)(ii)(A) “All 125-volt, single-phase, 15-, 20-, and 30-ampere receptacle outlets that are not part of the permanent wiring of the building or structure and that are in use by personnel shall have ground-fault circuit-interrupter protection for personnel.”

And if an employee is injured or worse, using a portable power pack, then I have little doubt OSHA’s investigators would carefully review UL 2743 and if anything wasn’t followed by employer according to the UL standard then the General Duty Clause would seem to be their default ‘catch-all’ citation at a minimum, but this is only my personal opinion. I have a pretty strong relationship with ADOSH (AZ OSHA) and I’ll have to run this by them the next time I’m at their office for their thoughts and if they’ve ever run into this.

Thanks for asking a great question and stay safe out there.