Focus on OSHA Requirements

In Part 1, we focused on the various definitions from OSHA and the NEC® as they relate to portable electric generators and that OSHA regulations are the law for workplace safety.

Now, in Part 2, we’ll start answering the age-old question, “What are the grounding requirements for portable generators?”

Since we will be speaking specifically of workplace safety, we must focus our attention primarily on the OSHA requirements pursuant to 29 Code of Federal Regulations (CFR) simply because it’s the law that governs safety at work.

Many people find it surprising that OSHA addresses grounding of portable and vehicle-mounted generators within their regulations because they can be easily purchased at your local Home Depot or other retailers for use at home or at work.

Thankfully, unlike many other OSHA governances which tend to be vague and subjective at best because they follow OSHA’s typical performance-based format, grounding portable generators is quite detailed and prescriptive. These very thorough instructions will aid in adequate compliance without diverting us to a host of other standards as is often the case with OSHA regulations.

Not Just One but Four OSHA Standards

Another interesting fact is this topic (grounding portable generators) is not limited to only one OSHA standard but is listed in all four of OSHA’s electrical safety regulations, covering electric utilities, who generate and deliver electricity to customers, and to the companies who utilize electricity either during construction or during maintenance.

Grounding and bonding portable generators is found in 1910.269(i)(3) Subpart R for electric power generation, transmission and distribution (T&D), but also 1910.304(g)(3) Subpart S for electrical utilization equipment within the General Industry standard. It then crosses into OSHA’s construction standard starting with 1926.404(f)(3) Subpart K for electrical construction and 1926.956(c) Subpart V during the construction of electric power transmission and distribution infrastructure.

And while all four regulations are identical in application and mandate the same conditions for worker safety, there are slight differences in the specific wording and verbiage used between them which can add unnecessary confusion. To simplify the details, we’ll dissect the common denominators from the four OSHA standards to ferret out the essential elements.

So, regardless of what occupation you work in, whether you use portable generators at construction sites, during maintenance activities, within or without the electric utility industry or other workplaces, these practices will help you first ensure the safety of your workers and, secondly, comply with regulations.

Voltage Limit?

Additionally, the OSHA regulations do not set a voltage limit for the portable generator’s nominal system output when they apply, which means it doesn’t matter if it’s a single-phase two-wire 120v, three-wire 120/240v, three-phase four-wire 277/480v generator or any other voltage.

IF/THEN

That said, the following four “IF/THEN” bullet points are the foundation for determining when the OSHA regulations for portable generators will apply. Please note the words in italics because their definitions were provided in Part 1.

If the portable and/or vehicle-mounted generator meets any one or more of the following conditions…

- If used to supply power to cord and plug connected equipment through a receptacle

- If used to supply power to equipment located on the generator or vehicle

- If mounted (permanently) on a vehicle

- If a component of a separately derived system (Note: When a portable generator is used for any of the three previous conditions, it is providing electrical energy as a separately derived system.)

…then the portable and/or vehicle-mounted generator must comply with all five of the following OSHA mandates:

- Then the metal frame of the generator need not be grounded – “earthed” – and can serve as the grounding electrode.

- Then the metal parts of the generator and the equipment grounding conductor shall be bonded to the generator frame.

- Then the grounded conductor shall be bonded to the generator’s frame .

- Then any neutral conductor shall be bonded to the generator’s frame.

- Then the generator’s frame shall be bonded to the vehicle’s frame, if mounted on a vehicle.

Therefore, when the portable generator being used meets any of the four “IF” criteria listed above, all the proceeding five “THEN” mandates must be in place. Since the four “Ifs” are self-explanatory, we will focus our attention on the five “THEN” conditions.

Explaining the 5 “Then” Statements Further

To better understand these five requirements, we’ll cover each one individually with a detailed explanation for a complete picture of what they entail.

First Requirement

Grounding the generator by connecting its metal frame to “earth” through a ground rod, connection to a ground grid, ‘ufer’ (concrete encased electrode), or any other grounding electrode, is not required because the metallic frame itself fulfills this purpose.

The only time the frame of the generator must be grounded, i.e. “earthed,” is when the portable generator is being used for something else outside of the four “IF” parameters or when the listed and labeled instructions from the manufacturer of the generator dictate grounding in accordance with OSHA 1910.303(b)(2) and 1926.403(b)(2). However, there is nothing preventing an employer from doing so if they choose.

Second Requirement

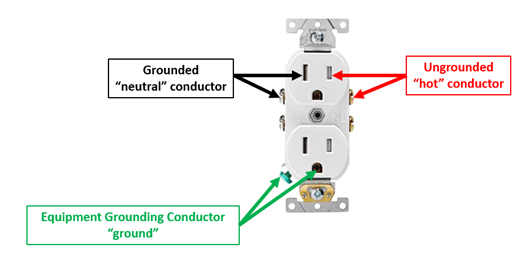

All metal parts of the generator, frame, bolts, guards, gasoline tank, engine, etc. must be bonded to the equipment grounding conductor (EGC). The EGC provides a low impedance path for fault current and is identified by insulation colored green or green/yellow or can be a bare copper conductor.

This is identical to the EGC found in a permanent installation where the EGC can also consist of bolted connections, metal conduits such as rigid, IMC and even EMT, that electrically connect (bond) all the non-current carrying metallic parts and enclosures together.

At the receptacle outlets, the female ‘ground port’ houses the EGC, as shown in green in Figure 1. The EGC is essentially the insurance policy to ensure all the metal parts will not become and remain energized if a ‘hot’ wire, AKA ungrounded conductor, shown in red in Figure 1, inadvertently contacts them.

When properly bonded, all metallic parts will remain at the same electrical potential (an equipotential zone) following a ground fault and will immediately trip the overcurrent protection device (OCPD) and de-energize the circuit.

Third Requirement

The grounded conductor is usually called the “neutral” or “common” by many electricians. It’s an active part of the circuit which carries return current from the load back to the source and is identified by white or gray colored insulation. At the receptacle outlets, the wider female slot houses the grounded/neutral conductor, as shown in black in Figure 1. The neutral conductor is connected to the neutral point in the portable generator’s windings, which will be covered in Part 3.

In a solidly grounded electrical system, which applies to portable generators, the neutral is intentionally connected to ground (for portable generators, the frame serves as the grounding electrode), thus the name grounded conductor.

The parallel example in a permanent installation will be the Main Bonding Jumper (MBJ) installed inside the service panel as required by the NEC® 250.28, which electrically connects the ground bus with the neutral bus. Simply put, the “grounded conductor” is the “neutral conductor” when speaking of portable generators and must be bonded to the generator’s metal frame members.

But one important point should be made about neutrals: not all neutrals are always grounded, such as those used in an ungrounded ‘floating’ system, but all grounded conductors serve the function as a neutral conductor. We’ll discuss this in greater detail in a later part.

Fourth Requirement

Since the neutral conductor is the same as the grounded conductor when speaking of portable generators, this mandate is fulfilled by implementing the previous (third) requirement.

Fifth Requirement

This is the only one that is conditional, based on whether the portable generator is permanently mounted or secured to a vehicle, motorized or not, such as trucks or trailers, etc.. If this condition exists, then the bonding must extend from the generator’s frame to the frame of the vehicle. Doing so places and maintains the vehicle’s metallic frame at the same electrical potential (equipotential zone) as the generator’s frame if a ground fault occurs.

Therefore, the most important aspect isn’t the physical grounding of the portable generator by simply connecting it to the earth but rather to verify both its neutral (grounded conductor) and the EGC is adequately bonded to the generator’s frame.

Conclusion

In Part 3, we will discuss several ways on how to know for sure that our portable generators are safe and legal for use in the workplace.