The 2020 National Electrical Code has rolled out a host of changes.

Some, in my opinion, have been long overdue. Just as an example, the 2020 NEC has four brand new articles, Articles 242, 311, 337, and 800. This came after 3700-plus public inputs and 1400 revisions!

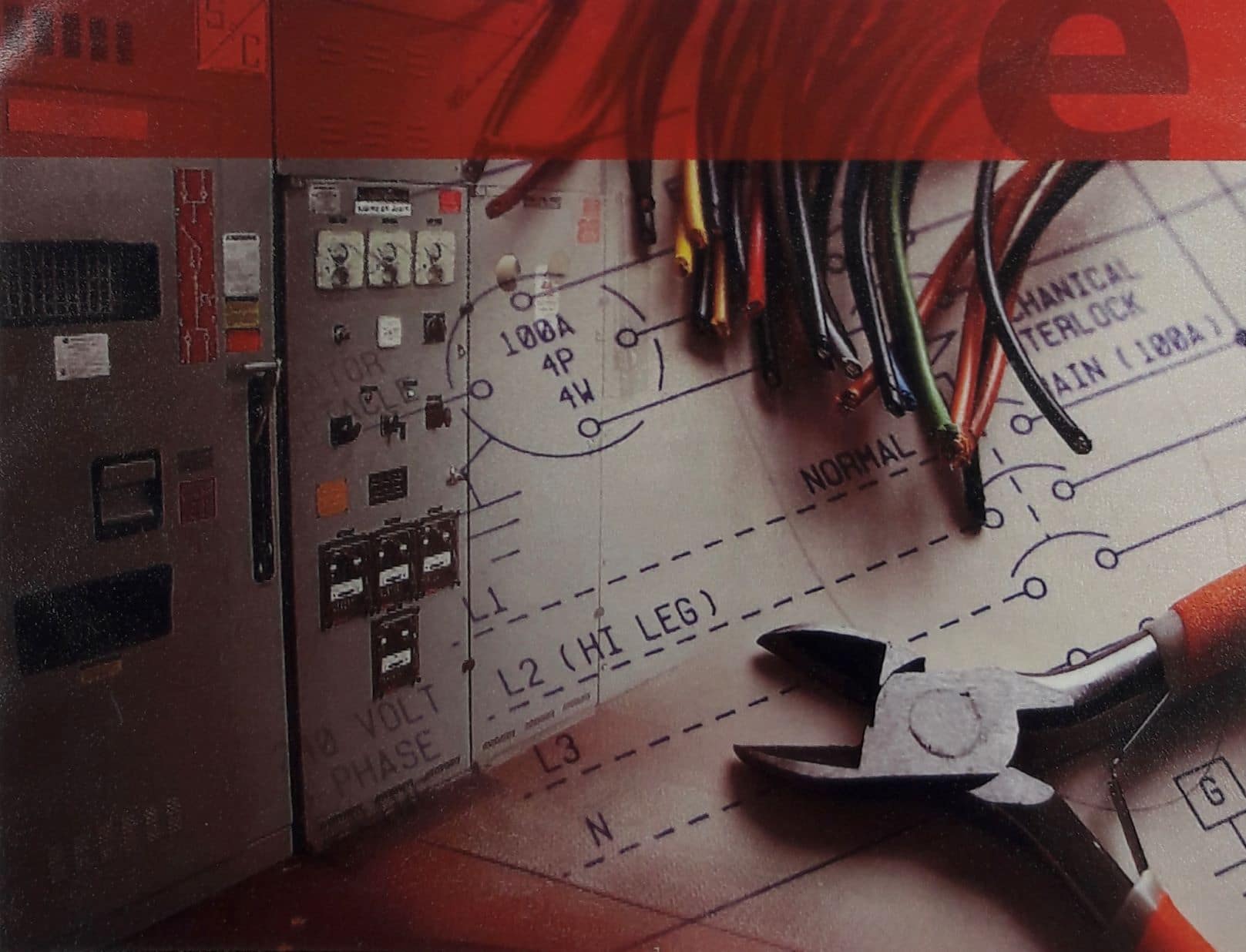

In this article, we’ll discuss one of the first changes. It appears in Article 110.22 – Identification of Disconnect Means.

Article 110.22(A) states:

“Each disconnecting means shall be legibly marked to indicate its purpose unless located and arranged so the purpose is evident. In other than one- or two-family dwellings, the marking shall include the identification of the circuit source that supplies the disconnecting means. The marking shall be of sufficient durability to withstand the environment involved.”

The wording here is well-phrased and specifically mentions a clear “purpose” of the disconnect means. In other words, one should never have to guess what the disconnect is providing power for. Anything beyond a visible conduit to a local load indicates a clear cut need for proper labeling of the disconnect.

The “identification of the source that supplies the disconnecting means” is a critical addition to the 2020 NEC. For ALL disconnects, the associated power supply must now be clearly indicated on a label that is legible and clear! So much for disconnects that have no labels whatsoever, or those I have seen that simply say “motor” with no motor anywhere within sight.

OSHA Subpart 1910.303(e) has addressed the requirement for labeling electrical equipment for years.

The OSHA statement, however, is a little vague. It is worded as follows:

1910.303(e) Marking—1910.303(e)(1) Identification of manufacturer and ratings. Electric equipment may not be used unless the following markings have been placed on the equipment:1910.303(e)(1)(i) The manufacturer’s name, trademark, or other descriptive marking by which the organization responsible for the product may be identified; and

1910.303(e)(1)(ii) Other markings giving voltage, current, wattage, or other ratings as necessary.

The “other markings…as necessary” statement leaves a wide path for interpretation. Having spoken over the years to several Federal and State OSHA inspectors, I consistently hear a basic tenet: these “other markings” should include the panel voltage, the panel ampere rating, the name of the panel, where it derives its power, and any and all equipment it feeds. This sounds reasonable for any electrical installation. Any electrician, engineer, or technician would certainly appreciate seeing a label with such appropriate information in a readily-available format.

NEC is Law

The 2020 NEC change referenced above certainly brings a legal perspective (enforceable by law once adopted by the state). The requirement to identify the equipment disconnect as to its purpose and its subsequent power supply in a method that will hopefully last the life of the panel itself will remove confusion by making these items crystal clear. I, for one, have seen enough “labels” that faded out in the 1970s and were never corrected, leaving the equipment’s details for a private eye to discover. This is truly unacceptable in our industry.

Other references for labeling electrical equipment appear throughout the 2020 NEC, as the following excerpt from 408 Switchboards, Switchgear, and Panelboards states:

408.4(B) Source of Supply. All switchboards, switchgear, and panelboards supplied by a feeder(s) in other than one- or two-family dwellings shall be permanently marked to indicate each device or equipment where the power originates. The label shall be permanently affixed, of sufficient durability to withstand the environment involved, and not handwritten.

In addition to arc flash labels, nominal voltage, and any other necessary markings, the following example shows what one should see when approaching electrical equipment:

Labels similar to this remove any guessing game as to the equipment’s purpose, and provide direction for quick access to panel or equipment supply in the case of a need for urgent disconnection. Let’s all do our part in ensuring electrical equipment is properly identified, and, by all means, keep electrical safety at the forefront of our minds.

Pingback: NEC Changes Part 3: Use and Identification of Grounded Conductors

Ken,

I cant seem to find anything in regards to a question that came up in a class I was teaching in regards to if someone has medically implanted screws, bolts, or plates does that pose a hazard like other metal objects we say remove like jewelry, keys, belt buckles, etc? Should they not do electrical work?

The standards would not have any statements about individuals internal metal as these would ONLY receive current IF the worker contacted electrical parts. I know of no incidents in which internal metal has been considered an increaser of injury and no standard addresses or requires any difference on such individuals to our knowledge.

Good hearing from you!

The NEC would not address safety issues like this – even with exposed metal objects on the body, like jewelry, finger rings, etc. You could turn to OSHA 1910.333 or NFPA 70e for guidance, but none of these standards get that specific. They address conductive items like tools, metal safety glasses, and conductive objects in general. OSHA 1910.333 states “1910.333(c)(6) “Conductive materials and equipment.” Conductive materials and equipment that are in contact with any part of an employee’s body shall be handled in a manner that will prevent them from contacting exposed energized conductors or circuit parts. If an employee must handle long dimensional conductive objects (such as ducts and pipes) in areas with exposed live parts, the employer shall institute work practices (such as the use of insulation, guarding, and material handling techniques) which will minimize the hazard.” 1910.333(c)(8) makes similar comments on conductive apparel.

Since implants are not “exposed”, they are really not a concern in regards to presenting a shock risk. There is no reason people with implants should stop electrical work for that reason.

Unless it was a wild goose chase, I was told d to look at the code as far as verbiage. Should any equipment or disconnect be labeled as “fed by” or “fed from”

Sorry for the delayed reply. The 2020 NEC does address fed from requirements. Article 110.22 of the 2022 NEC states the following: ”

(A) General. Each disconnecting means shall be legibly marked to indicate its purpose unless located and arranged so the purpose is evident. In other than one- or two-family dwellings, the marking shall include the identification of the circuit source that supplies the disconnecting means. The marking shall be of sufficient durability to withstand the environment involved.”

This is where the idea of “fed from” labels originates. It is critical that switches, circuit breakers, and the like are clearly noted as to where they are supplied from for multiple reasons.

No service equipment . Is it the label to go on the outside disconnect

If the panel you are referring to is a circuit breaker panel or fused panel with multiple loads, then an inside legend is perfectly fine as long as it is legible. However, the actual panel identification, fed from label, and voltage should be prominently displayed on the exterior, making it obvious to personnel critical information for a variety of safety reasons.