Infrared Scans - A Predictive Tool

In these days of tight budgets and limited resources, every expenditure is highly scrutinized. I cannot tell you the number of times I have heard a maintenance manager say, “We don’t fix things until they are broken.” This attitude may work for some few occupancies; however, most manufacturing facilities can ill-afford the cost of repairs and loss of revenue associated with an unscheduled shutdown.

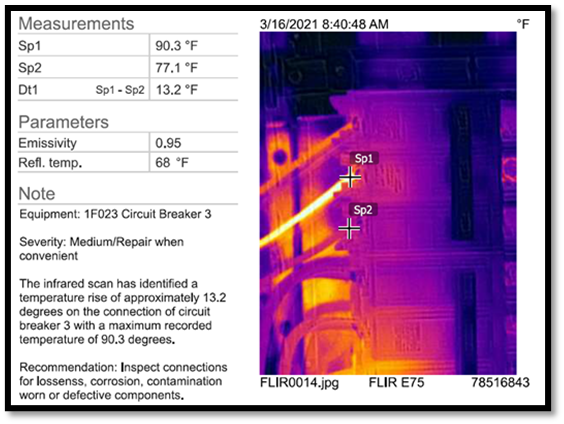

Infrared scans (IR) are an important part of any Preventative Maintenance or Risk Assessment Program. They are one of the few predictive tools we have that allows the user to anticipate an equipment failure while it is still operational and appears normal. It has the added benefit of being performed on energized equipment. This means you do not need to schedule an outage to get extremely beneficial and accurate data regarding the health of your electrical equipment.

All electrical equipment has a maximum temperature rating where, if exceeded, will cause mechanical damage to the components, reduce the dielectric strength of the insulation, and shorten the useful life. Loose or corroded terminations, overloads, unbalanced loads, and high ambient temperatures are all detrimental to the health and functionality of electrical components. A single Infrared scan can identify all these conditions simultaneously.

The probability of identifying these conditions prior to failure, without infrared scans, is practically zero. Since electrically conductive materials are also thermally conductive, a poor conductance at the termination to a circuit breaker will transmit heat to the internal components of the breaker. This lowers the ampacity at which the breaker will trip on overload causing nuisance tripping. Infrared scans will identify the specific location of any circuit, termination, or component headed towards failure. Rather than having to disconnect and re-terminate an entire forty-two circuit panel, you only need to repair those generating excessive heat.

IR - A Reliable Tool

Early identification of a potential catastrophic failure allows you to schedule remedial action during normal operations, conserving resources and assuring maximum use of the investment of production equipment. Unscheduled shutdowns are the bane of the maintenance supervisor existence, causing stress and exacerbating the probability of the application of Murphy’s Law.

“Hoping nothing bad happens” is not a strategy! Use the tools available. Infrared Scanning is the most reliable diagnostic tool to determine the health of electrical equipment and the best predictor of possible catastrophic failure.

If You Need More Info...

Go to our website to learn more about e-Hazard’s Thermal or Infrared Electrical System Scan.