A while back, I wrote an article called Let’s Have a Torque Talk. As a follow-up, let’s dive a little deeper into specific examples and the driving forces behind proper electrical torque.

Do You Know the Torque Values For…

- A standard 15- or 20-amp receptacle?

- A typical 15- or 20-amp circuit breaker?

- A main lug on a 200-amp commercial or residential panelboard?

- A socket screw connector for an electrical connection?

So, exactly what values is the user supposed to torque the following items to?

Refer to Manufacturer’s Specs

As discussed in the previous article, the first stop is always the manufacturer. Manufacturers of listed/labeled electrical devices are required to provide proper torque specifications. These are specific to the decisions made by manufacturer engineering teams, often based on failure testing models at device designed amperage limitations.

UL Certifications

Guidance for manufacturers is also given by the following Underwriter’s Laboratory certifications:

UL 498 – Attachment Plugs and Receptacles

UL 20 – General Use Snap Switches

UL 486 A-B Wire Connectors Table 21 – Tightening Torque for Screws (Slotted Head No. 10 and larger, split-bolt connectors, and other connectors)

UL 486 A-B Wire Connectors Table 22 – Tightening Torque for Slotted Head Screws Smaller than No. 10 [intended for use with 8 awg (8.4 mm2) or smaller conductors].

UL 486 A-B Wire Connectors Table 23 – Tightening Torque for Screws with Recessed Allen or Square Drives

UL 486 A-B Wire Connectors Table 24 – Tightening Torque for Connecting Hardware

NFPA® 70® Informative Annex I

These UL 486 torque values are included in the National Electrical Code® in Informative Annex I – “Recommended Tightening Torque Tables from UL Standard 486 A-B.”

For example, UL 486 A-B Table 21 specifies that a size 10 slotted head screw for size 12 awg wire is specified at 20 in-lbs. if the slot width is 1.2mm (0.047”) or less and slot length is 6.4 mm (1/4”) or less.

Anyone have a tiny ruler handy? The same 12 awg wire in a split-bolt connector would need to be torqued to 9 Newton-meters, or 80 in-lbs. As wire sizes increase, torque values continue upward.

NFPA 70B®

How about a 3/8” recessed Allen drive? Well, according to UL 486 A-B, that would be a required torque of 42.4 N-m, or 375 in-lbs. You find references to these torque values also appearing in NFPA 70B 2023 Tables 7.2.1.4.2(a), (b), and (c).

The 70B Table 7.2.1.4.2(a), as an example, lists a bolt diameter of 3/8” at 20 ft-lbs. This torque is based on a national course thread pitch that is a grade of SAE 5. This table is titled “Bolt-Torque Values for Electrical Connections, US Standard Fasteners – Cadmium or Zinc Plated.”

Notice that this is a specific torque chart for a specific set of parameters. Again, 70B directs the reader to always follow manufacturer’s instructions when available. A unique take in 70B is mentioned in 7.2.1.4.1, which states the following:

“When using a calibrated torque wrench to confirm the torque of previously installed threaded hardware, the retightening value shall not exceed 90 percent of the manufacturer’s specified initial torque value.” (NFPA 70B Standard for Electrical Equipment Maintenance, 2023).

Examples

Let’s follow NFPA 70B and the NEC’s instructions and properly torque a common device – a duplex receptacle. As an example, let’s use a Leviton 5320-4, a NEMA 5-15R 125 Volt, two-pole, three-wire duplex receptacle. This one happens to be sold sans the typical receptacle “wings” that sit against a typical electrical enclosure. The receptacle looks like this:

Leviton expects the wires on this device to be torqued to a range of 14 to 18 in-lbs. You can find this value here, or in the device’s packaging, if you do not throw it in the trash too quickly.

Another example, with the exact torque value, is Legrand devices. All their devices that fit into the 15-, 20-, or 30-amp switch and/or receptacle category are 14 to 18 in-lbs, as shown here:

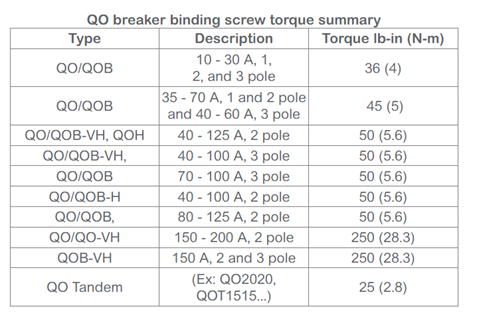

Let’s go a little bigger and look at a 20-amp circuit breaker. Square D’s QO series is a popular residential and commercial breaker brand. Square D conveniently embosses the required torque value on the side of the actual device but also provides the following chart:

Notice that this chart list values in both in-lbs and Newton meters, so one must be careful to use the correct value with the correct calibrated torque device.

In 2021, UL 498, the standard for Attachment Plugs and Receptacles, was updated to require that manufacturers specify tightening torque values for the wire-binding screw terminals and required these manufacturers to mark these torque values on the device itself, or on the smallest unit container, or the information sheet that is provided with the device. Next time you purchase a receptacle, be sure to search for the torque values.

Our Previous Article

You can refer to the previous article, Let’s Have a Torque Talk, to be reminded of why proper torquing of electrical connections is so critical. The key is to find the proper torque, use a calibrated torque tool (typically a torque wrench or torque screwdriver), and properly tighten each and every connection.

Contact us!

As always, feel free to contact e-Hazard for your electrical safety and code questions. We are here to help! Call our office at (502) 709-7235 or use the link below to send a message.