What is an Iso-phase Bus?

In Part 1, we covered some of the basics of electrical insulation testing and the hazards involved. Now, in Part 2, we’ll share a recent incident where an electrician received a very nasty electric shock while performing electric insulation testing at 15kVdc of an iso-phase bus.

For those not familiar with what an iso-phase bus is, I’ll provide a brief description. In large electric power generating plants, the generator’s output current is fed to the transmission grid through step up transformers, known as GSUs, or Generator Step Up, transformers.

The plant’s auxiliary transformer provides the station’s internal power needs by taping off the generator’s output before sending the remainder of the power to the grid. The generator is connected to the GSUs, auxiliary transformers and other equipment through three large individual bus segments designed with one bus per phase. Each phase bus is segregated from the others and is housed within its own enclosed bus duct that’s grounded and bonded to the station’s ground grid.

To maintain adequate separation of the energized bus from the grounded duct, rated ceramic insulators are used for this function. Since each phase bus is completely isolated from the other two, the term “iso-phase” was developed, meaning the three phases are completely isolated from each other.

Since the iso-phase is a massive rigid bus, large flexible links are used to connect the bus to the various transformers and generator output.

Incident Involving Electric Insulation Testing

Prior to testing the iso-phase bus, all the flexible link connectors to the generator, GSUs, auxiliary transformer, and other equipment are disconnected to create an adequate air space between the links and bus connections to ensure the bus is completely isolated, or “floating.” This condition allows the insulation testing to be limited to only between the bus, the grounded duct, and the ceramic insulators.

During testing, the crew of electricians was receiving unacceptably low resistance levels with the “B” phase of the iso-phase bus during high voltage electric insulation testing. At such high voltages, minute levels of current leakage can occur through inadequate air gaps compounded by humidity and temperature variations, which can affect test readings in a negative manner.

A determination was made to recheck all the flexible links to assure themselves that adequate separation from the bus existed at all the devices. Two electricians from the crew departed the testing location to visually inspect the other parts of the bus for any anomalies.

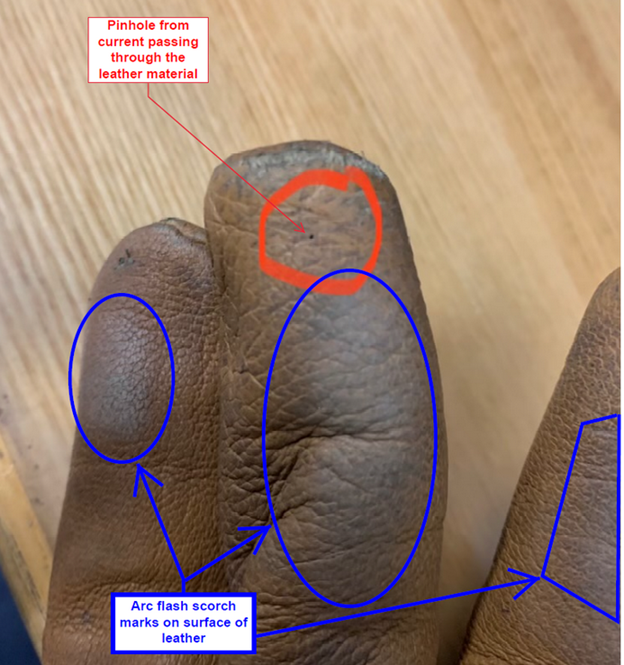

With the “B” iso-phase bus still energized by the test instrument, one of the electricians inadvertently made contact with the bus, resulting in an electric shock. Even though he was wearing thick leather work gloves (not voltage rated), the voltage pressure was sufficient enough to penetrate the leather material, creating a pinhole through the leather material. This permitted the current to reach his fingertip and cause a small burn to the tip of his middle finger.

Additionally, there were also scorch marks from a small arc flash, not only in the area surrounding the entry pinhole, but also on the exterior surface of the glove’s adjacent index and ring fingers which are identified within the blue outline in the photo. It would be safe to surmise, even though the leather work gloves were the wrong PPE for the hazard, the burn injuries would have been more severe if the injured worker wasn’t wearing any gloves. Thankfully, the electrician wasn’t seriously injured. But we can’t rule out the fact it could have ended differently.

Proper PPE

This brings me to another related but separate electrical safety subject. The leather work gloves, or the leather protectors worn over rubber insulating gloves, do not provide any shock protection. Only the rubber gloves themselves are designed and tested to a certain voltage level with a corresponding class rating.

The leather protectors’ sole purpose is to provide the rubber glove with a robust barrier to protect it from physical damage, such as punctures, cuts, abrasions, etc. Therefore, never wear leather protectors without your rubber insulating gloves, and never rely on standard leather gloves to protect you from electric shock, regardless of the voltage.

Electrical Safety Precautions

Interestingly, the Megger® corporation released an excellent white paper titled “A Stitch in Time – A Complete Guide to Electrical Insulation Testing” [1] which not only explains, in great detail, the specifics of insulation testing and the different types of “megger” tests but, more importantly, some crucial electrical safety precautions when using the test equipment. (Click here to immediately download your own copy of this paper.)

For example, the following key points are shared, which must be carefully followed by the user:

- “Observe all rules for safety when taking equipment (to be tested) out of service.” – meaning such things as wearing safety glasses, applying Lockout/Tagout, using barrier tape, etc.

- “Never connect a Megger® insulation tester to energized lines or equipment.” – meaning the equipment to be tested must be de-energized.

- “It is very important that capacitance be discharged, both before and after an insulation resistance test.” – meaning equipment must be shorted and grounded outside of the actual testing window.

- “Test for foreign or induced voltages.” – meaning the use of an adequately rated test instrument to verify the absence of voltage.

- “Use rubber gloves when connecting the test leads to the apparatus and while operating the Megger® instrument.” – meaning the electrician’s best PPE for preventing electric shocks when the hands will cross into the Restricted Approach Boundary of energized exposed parts is also necessary to protect you from a shock from your test equipment.

- “Do not use the instrument in an explosive atmosphere.” – meaning insulation testing can cause sparks during testing and even small sparks can cause ignition.

- “Shock hazard from test voltage. Observe the voltage rating of the Megger® instrument and regard it with appropriate caution.” – meaning the voltage offered by the test instrument can present a serious shock hazard to the user and others in close proximity.

- “Large electrical equipment and cables usually have sufficient capacitance to store up a dangerous amount of energy from the test current.” – This was the case in point with the iso-phase shock incident described above.

More Electrical Safety Practices to Follow

Apart from the great safety information derived from that white paper, here are a few more safety practices that should also be considered.

- Ensure all members of the testing team are continually communicating with one another regarding the status of the testing.

- Use human performance (HU) error prevention tools to minimize mistakes. Informational Annex Q, “Human Performance and Workplace Electrical Safety” from NFPA® 70E is a great resource for this underused tool.

- Post attendants or barricade with barriers and warning signage to keep other workers who are not involved with the testing out of harm’s way.

- If there are any current transformers (CT’s) in the circuit to be tested, ensure the secondaries are shorted.

- And, lastly, there is no shame in asking for assistance from your leader or supervisor if unexpected conditions are encountered during testing.

Insulation testers are great resource for electrical workers but, like any other tool, if they are not used correctly according to the manufacturer’s safety instructions, then these wonderful assets can become a dangerous liability to your safety.

What a coincidence – I was at a site where a worker got “meggered” on a Isophase bus . they were not injured but the one doing the meggering was almost ‘injured” by the victim.

LOL, I can relate because the one and ONLY time, I was taught firsthand how a megger worked from a seasoned old prankster, who was posing as a jouneyman electrician, I too nearly injured him.

Good article George. As an electrician, knowing and understanding the hazards of the equipment you are working on is a must, along with what hazards you are introducing with the test equipment that is being used to PM it so that proper preparation and safety measures are deployed for everyone’s safety.