Typical Grounding Procedure

In the electric utility industry, the practice of using temporary protective grounding (TPG) for systems above 600 volts has been normative for years as part of the creation of a safe work condition.

The typical method will include system switch line-up isolation for deenergization, lockout or tagout-only procedure through a utility clearance via an approved switching order, then followed by an absence of voltage “live-dead-live” check, either by a non-contact proximity detector or through a properly voltage rated contact meter.

Don’t Do This!

As a safety side note, some readers may still be using the old and very dangerous “buzzing” or “fuzzing” the overhead line/equipment technique to verify that the line/equipment is deenergized. This unreliable practice was common decades ago when high voltage detection equipment was not readily available. But thanks to today’s technological advancements, proper test instruments, rated for distribution and transmission voltages, are readily available.

These detectors and/or touch meters can determine with 100% certainty that the conductor about to be grounded is truly absent of nominal system voltage. If any readers are still using fuzzing/buzzing techniques, e-Hazard strongly recommends that this activity be stopped, and that proper testing devices and techniques be utilized. Personnel performing this type of improper verification are playing Russian roulette with their own safety.

Regulation

Temporary grounding is fundamentally founded and dependent upon properly deenergizing the lines or equipment and ensuring that those lines/equipment remain in that safe condition. To better understand the regulatory de-energization mandates, this article will take a deeper look into the actual requirements of OSHA 1910.269, subpart R on this topic, and its connections to 1910 subparts J and S.

OSHA 1910.269(m), Subpart R, Transmission and Distribution

Section (m) is titled “De-energizing lines and equipment for employee protection” and applies to de-energization of transmission and distribution lines and equipment for protecting employees.

An easily-overlooked but very important statement appears in the Application directives of 1910.269(m)(1):

“…See paragraph (d) of this section for requirements on the control of hazardous energy sources used in the generation of electric energy….”

The idea presented here is that electric generation plants, regardless of how electricity is generated, must take a different approach in controlling hazardous electrical energy. Let’s take a momentary rabbit trail to the prescribed methods for controlling hazardous energy within electric power generation.

OSHA 1910.269(d), Subpart R, Generation

This section is titled “Hazardous Energy Control (lockout/tagout) Procedures” and its Application section states the following:

Application. The provisions of paragraph (d) of this section apply to the use of lockout/tagout procedures for the control of energy sources in installations for the purpose of electric power generation, including related equipment for communication or metering. Locking and tagging procedures for the deenergizing of electric energy sources which are used exclusively for purposes of transmission and distribution are addressed by paragraph (m) of this section. (emphasis added)

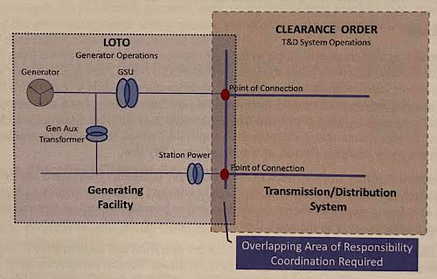

EPRI’s Switching Safety and Reliability Reference Book, better known as the “Black Book,” has a diagram that clearly defines the demarcation between LOTO for generation per 1910.269(d) and clearance orders for T&D per 1910.269(m), as shown by Figure 1 below. The overlap between T&D clearances and generation LOTO must be carefully planned and coordinated between the power plant and grid operator.

In section (d), we are redirected to section (m) for transmission and distribution, similar to how paragraph (m) points to (d) for generation, but let’s stay focused on generation for a bit. If we peruse section (d), we find statements like “energy control procedures” and “energy control program.” Section 1910.269(d)(2)(ii) actually provides a listing of specific energy control program requirements for electric power generation, including the allowance of a tagout only system if devices are not lockable. This tagout only provision must provide the equivalent level of safety for employees obtained through a lockout program. (If lockable, they must be locked unless tagout provides “full employee protection” [1910.269(d)(2)(ii)(B)].

If you read through the entire provisions and requirements in section (d), you will finally come upon a note in 1910.269(d)(8)(v)(C):

Note to paragraph (d): Lockout and tagging procedures that comply with paragraphs (c) through (f) of § 1910.147 will also be deemed to comply with paragraph (d) of this section if the procedures address the hazards covered by paragraph (d) of this section.

In other words, the entirety of section of 1910.269(d) of subpart R is built upon the same concepts as 1910.147 of OSHA subpart J, which is also titled, “The control of hazardous energy (lockout/tagout).” Sound familiar?

When 1910.269(d) refers the reader to paragraph (m) for T&D and 1910.269(m) redirects back to paragraph (d) for generation, it is a clue that there must be a good reason for OSHA to provide such detailed and prescriptive directives.

One main reason is because the electrical systems and equipment used in generating plants, other than the generator itself and the generator step up (GSU) and auxiliary transformers, are very similar, if not identical, to those commonly found in large industrial facilities. Therefore, it makes sense to follow the same approach to hazardous energy control that is covered under the 1910.147 umbrella.

However, there is another exemption that needs to be discussed within this context. Keep reading!

OSHA 1910.147, Subpart J, Control of Hazardous Energy (Lockout/Tagout)

If we read further into the exemptions of 1910.147 subpart J, it does NOT cover… drumroll please… “Installations under the exclusive control of electric utilities for the purpose of power generation, transmission and distribution, including related equipment for communication or metering” [1910.147(a)(1)(ii)(C)].

But, according to what we just read above in 1910.269(d)(8)(v)(C) subpart R, IF a LOTO program meets 1910.147(c)-(f) in subpart J, then a generation facility should be in good shape, but only if the electrical hazards are also adequately addressed. So, let’s temporarily move past the “NOT COVERED” section of subpart J and keep going forward. Sometimes stubbornly plodding forward through OSHA regulations is helpful to grasp an accurate understanding within its context.

1910.147(c) subpart J is the Energy Control Program, and, amazingly, looks very similar to the verbiage in 1910.269(d) subpart R. It likewise covers locks, tags, audits, training, communication, application of locks/tags – the works. The breakdown of sections 1910.147(c)-(f) are as follows:

Section (c) – General (energy control program)

Section (d) – Application of Control

Section (e) – Release from Lockout or Tagout

Section (f) – Additional Requirements (testing, outside personnel, group LOTO, shift change, etc.)

So, for the generation parts of the plant, the employer has a choice to follow either section (d) of 1910.269 subpart R, or the equivalent – almost identical – requirements in 1910.147 subpart J, sections (c)-(f), as long as the electrical hazards are properly addressed.

Are you confused enough yet? If not, hang on. Hopefully, this article will help alleviate some of the confusion.

Scrolling down a little more in 1910.147 subpart J, to the exemptions of “electrical energy not covered here” disclaimer, (as if two exemptions were not already enough), we stumble upon a third exempting statement in 1910.147(a)(1)(ii)(D):

Exposure to electrical hazards from work on, near, or with conductors or equipment in electric-utilization installations, which is covered by subpart S of this part…

So, if there is exposure to electrical hazards under the LOTO provisions of 1910.147 subpart J, related with “electric-utilization installations,” the reader is directed to 1910 subpart S, which is specifically found in 1910.333 “Selection and Use of Work Practices”.

What does it mean by “electric-utilization installations?” To answer this question, the reader will need to move back to 1910.269 subpart R, and especially to the note in 1910.269(d)(1). This note clarifies that any structures, buildings and facilities at power generating plants, that are NOT “an integral part of, or inextricably commingled with the power generation processes or equipment,” such as warehouses, office buildings, garages, machine shops, recreational buildings, cafeterias, etc., then the employer must control hazardous electrical energy through the LOTO process as delineated by 1910.333(b) subpart S “Working On or Near Deenergized Parts” and definitively by 1910.333(b)(2) “Lockout and Tagging.”

But any electric equipment, conductors or lines at the power generating plants directly related with the generation process or environment must be controlled by 1910.269(d) of subpart R.

Without intending to add further confusion to the mix, for those readers who are familiar with NFPA® standards and codes, essentially the same demarcation exists within the scope of both NFPA 70E® Electrical Safety in The Workplace® and NFPA 70 National Electrical Code® (NEC) as contained in their “covered” and “not covered” criteria pursuant to articles 90.2(A) and 90.2(B).

Is everyone now clear on lockout/tagout and/or clearance requirements? Whew! We haven’t even started the good stuff yet – GROUNDING!

Next up: Part 2

In Part 2 of this series, the authors will get off the rabbit trail of controlling hazardous electrical energy for the time being and back to the main discussion point – Temporary Protective Grounding for the protection of employees.

Great read and resource. Thanks!

Thanks so much for your feedback. Much appreciated. Articles 2-4 are on the way!