Definition of "De-energized"

The term “de-energized” is common among electrical workers, but understanding its significance can vary greatly depending on the person you speak with. However, did you know it’s actually defined by safety regulations and industry recognized standards?

In fact, OSHA 29CFR 1910.399 – Subpart S and NFPA 70E® * article 100 both define ‘de-energized’ as “Free from any electrical connection to a source of potential difference and from electrical charge; not having a potential difference from that of earth.”

Another word for “potential difference” or “difference of electric potential” is “voltage,” so de-energized is a state that’s free of voltage. At face value, this statement seems fairly elementary, but we need to start peeling the layers of the “electrical safety onion skin” to gain a complete understanding.

When standards and codes define words, the purpose is to ensure all readers will have the same comprehension of its meaning, parameters, and limitations. This helps reduce confusion, provide consistency, and minimize personal interpretations between individuals while navigating the codes or standards. However, even with technical definitions provided, they must be further understood within the full context of the standard or code.

No Voltage Present - But Is It De-energized?

Most electricians and technicians will agree working on electrical equipment that has been “de-energized,” i.e. no voltage present, offers the greatest level of safety from electric shock and arc flash hazards. And, while true, it’s only partially true.

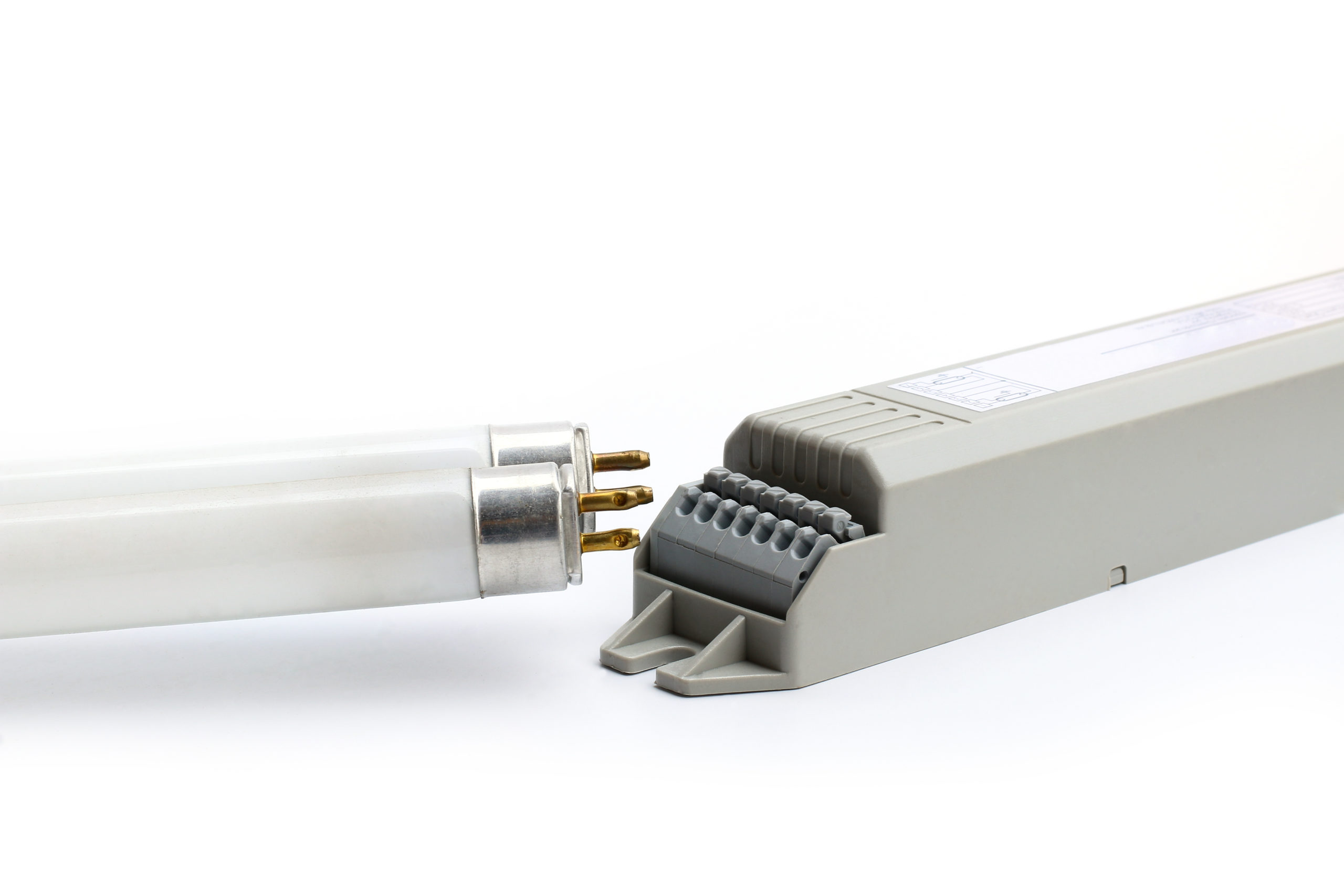

Take, for example, the relatively common activity of changing out a 277-volt ballast in a fluorescent lighting fixture. Obviously, removing the wire nuts with the power on is inherently riskier than doing so with the power off. And moving the wall switch or circuit breaker to the “off/open” position, should remove any voltage and current to the luminaire. Technically speaking, the ballast is de-energized according to the definition. But is the lighting fixture actually de-energized, and is it safe to work on according to safety regulations? This is where we must temporarily exchange our electrician’s hard hat with one from a safety consultant.

What More Is Needed?

To answer the question in the previous paragraph, we need to look at OSHA 1910.333(b) – Working on or near exposed deenergized parts, for a better understanding, especially as we progress to 1910.333(b)(1) – Application, which states: “This paragraph applies to work on exposed deenergized parts or near enough to them to expose the employee to any electrical hazard they present. Conductors and parts of electric equipment that have been deenergized but have not been locked out or tagged in accordance with paragraph (b) of this section shall be treated as energized parts, and paragraph (c) of this section applies to work on or near them.” (Emphasis added)

This section applies to “exposed deenergized parts” in the first sentence, and then throws a curve ball in the following second sentence. Even when no voltage is present at the lighting ballast because of the status of the wall switch or breaker with the lamps extinguished, unless the lighting circuit has been Locked Out/Tagged Out (LOTO) according to 1910.333(b)(2), it cannot be considered, nor treated as, deenergized.

LOTO Requirements per OSHA

So, the LOTO program plays an important role in electrical safety. But before applying our LOTO, we have other mandatory actions that must be fulfilled according to 1910.333(b)(2)(iii) (A) through (D) for the actual process of “deenergizing the equipment,” which requires all of the following conditions:

(A) Procedures to deenergize the equipment must be in place.

(B) The equipment must be disconnected (isolated) from all sources of electrical energy. Prohibits the use of selector switches, push buttons, control circuits, etc. as isolation devices.

(C) All stored electrical energy in capacitors must be discharged, shorted and grounded.

(D) All stored non-electrical energy needs to be blocked or relieved.

With these four prerequisite actions completed, we can now attach our LOTO to the isolation point(s), but before proceeding to the actual task of changing the ballast, a final two-step verification must also be accomplished, pursuant to 1910.333(b)(iv)(A) and (B).

(A) states: “A qualified person shall operate the equipment operating controls or otherwise verify that the equipment cannot be restarted.”

For a lighting fixture, this can be as simple as flipping the switch to the ‘on’ position to see if the lamps illuminate or pushing the ‘start’ button on a three-phase induction motor. But keep in mind that the attempt to restart the equipment may be adequate for a non-electrical worker such as the mechanic who is tasked with changing the coupling between the motor and gear box, but for the qualified electrical worker who is about to place his hands on the exposed “de-energized” wires of the ballast or inside the motor’s termination box, this must never be the last step. It’s for this reason we’re provided with sub-step (B).

(B) states: “A qualified person shall use test equipment to test the circuit elements and electrical parts of equipment to which employees will be exposed and shall verify that the circuit elements and equipment parts are deenergized. The test shall also determine if any energized condition exists as a result of inadvertently induced voltage or unrelated voltage backfeed even though specific parts of the circuit have been deenergized and presumed to be safe. If the circuit to be tested is over 600 volts, nominal, the test equipment shall be checked for proper operation immediately after this test.”

The directive of “B” means the circuit must be tested using test instruments to verify with 100% certainty that no hazardous voltage still exists on the exposed parts about to be touched. With the circuit breaker opened and LOTO, the de-energized conductors can still be energized at hazardous voltages independent from its normal source, by such things as electromagnetic induction, back feeds, wiring errors, damaged insulation, equipment malfunction, etc. It’s impossible for a human to detect electrical potential using his five sensory systems of sight, sound, taste, smell, and touch. (One may foolishly argue “touch” can be used, but doing so could be that person’s last touch.)

Therefore, from a position of compliance with electrical safety regulations, but more importantly worker protection, the ballast or motor leads can’t be treated as “de-energized” unless all of the actions listed above have been accomplished.

Going Beyond the Minimum Requirements

The apparent paradoxical conditions of the word “de-energized” by OSHA can bring about much confusion and ambiguity between different workers who failed to understand 1910.333 in its entirety.

However, those who desire excellence in their electrical safety practices that go beyond mere compliance alone look to NFPA 70E for further guidance because it paints a clearer picture and provides a more practical method to this end.

70E moves away from the use of the subjective word “de-energized” to a phrase consisting of four key words, Electrically Safe Work Condition (ESWC), to remove any confusion. While similar to OSHA’s multi-step, albeit disordered, process for an electrical circuit to be “de-energized,” NFPA 70E takes a logical and prescriptive approach through a detailed eight (8) step process that must be performed in specific order.

Electrically Safe Work Condition (per NFPA 70E)

The ESWC is found in Article 120.5 and is foundational for the elimination of electric shock and arc flash hazards as the top priority of NFPA 70E according to article 110.1.

Verification that an ESWC exists mandates all eight of the following steps have been accomplished in the prescribed order, if feasible:

- Determine all possible sources of electrical supply to the specific equipment by checking up-to-date drawings.

- Properly interrupt the load current; then open the disconnecting device(s) for each source.

- Visually verify that all blades of the disconnecting devices are fully opened or that drawout-type circuit breakers are withdrawn to the fully disconnected position.

- Release stored electrical energy.

- Block or relieve stored nonelectrical energy so parts cannot be unintentionally reenergized.

- Apply lockout/tagout devices in accordance with procedures.

- Use a rated portable test instrument to test each conductor or circuit part for the absence of voltage by testing both phase-to-phase and phase-to-ground. Before and after each test, verify the test instrument is operating satisfactorily on any known voltage source.

- Apply temporary protective grounds to develop and equipotential zone if induced voltages, re-accumulation of stored energy or a possibility of contact with other energized parts.**

As you can see, an ESWC not only contains all the OSHA obligations for a circuit to be treated as “de-energized” but also houses additional directives and lays them out in a logical systematic order with sufficient details for each step. By doing so, 70E purges any confusion by replacing the subjective word “de-energized” as used by OSHA with a distinct term “ESWC” that can’t be misunderstood.

Conclusion

When speaking of the health and safety of employees, rather than using the ambiguous word “de-energized” to describe the safe condition of electrical equipment, if we change the paradigm in our workplaces and start incorporating the term Electrical Safe Work Condition instead, then there will be no misinterpretation between all stakeholders.