Envision: Develop an ESP

1. Designate a core team to develop the electrical safety program. This team should include representatives from management, the engineering and electrical trades, and the safety department.

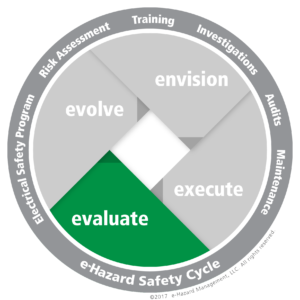

2. Because the initial development of the written ESP can be difficult, e-Hazard provides templates with the “bones” of an ESP in our Electrical Safety Compliance Strategies Class. (This program has been used by several Fortune 500 companies and also by many companies with fewer than 50 employees.) Don’t get hung up on this process and put off purchasing PPE, training, equipment labeling or completing an arc flash study while trying to get your ESP perfect. That is why we have developed the e-Hazard Safety Cycle™; throughout the cycle, you will keep improving your ESP by adding and revising parts with best practice