Using a Megohmmeter

Electrical insulation testing using a megohmmeter is a valuable tool to determine if the dielectric property of wires, cables, motor windings and other electrical equipment is adequate for the nominal system voltage prior to energization. It’s compared to pressure testing water pipes to see if there are any leaks, but only for electrons rather than water molecules.

Often called “meggering,” this term is actually a name brand for a company that supplies electronic test equipment and measuring instruments. Many other manufacturers produce high quality megohmmeters that can help electricians and technicians determine the health of insulation or if a “hard” or “soft” ground exists within electrical circuits and equipment during troubleshooting activities.

And while there are slight differences between insulation resistance testers compared with megohmmeters, for the purpose of this article and Part 2, these will not be covered since the focus is on worker safety rather than technical nuances.

Capability of Megohmmeters

With today’s modern-day megohmmeters, we’re able to determine the insulation’s resistance levels far greater than the kΩ (thousands of ohms) and even MΩ (millions of ohms) ranges, with values far into the realm of giga-ohm (GΩ), AKA 1.0 x 109 or billions of ohms of resistance. Voltages generated by the test instrument can be anywhere from several hundred volts up to several kilovolts (kV) depending on the model used and the specific need.

One of the greatest advantages of megohmmeters over other forms of insulation testing, such as high potential dielectric withstand testing (“hipot”) is that the former test is considered “non-destructive.” This means that if a fault or leakage current is detected through low resistance readings, the weakened resistance isn’t further damaged by the instrument.

In the “old days,” megohmmeters were large instruments that were hand cranked to generate the necessary high voltages necessary for testing with analog deflection meters to display resistance. Today’s modern units are digital, more portable, and use batteries and/or can be plugged into standard 120 VAC receptacle outlets.

Risks of Using Megohmmeters

As wonderful as these tools are for troubleshooting, analyzing degrading insulation trends, etc., they can pose some serious risks to the safety of the workers who use them and others in the vicinity of the equipment being tested if adequate precautions aren’t taken.

Most electrical workers are taught how to operate megohmmeters and to decipher the data being displayed, but this training seldom covers the safety risks associated with their use. While these instruments can output very high voltages and their current levels are throttled back to very low values, they still pose safety hazards to workers.

Some people compare receiving a shock from a megohmmeter as comparable to touching an electric fence designed to keep livestock in or out of an area. In fact, there was once a time in the electrical trade when apprentices were commonly taught firsthand how a ‘megger’ worked. What do I mean by “firsthand?” The journeyman would instruct the green apprentice to hold one test lead probe in each of his bare hands while directing him to “carefully lay out and not tangle the leads.” When the leads were laid out nice and straight on the ground and the journeyman was confident the apprentice was firmly gripping the exposed metal parts of the test probes, he would crank the handle with the whole crew laughing from the applied firsthand learnings.

Thankfully, this type of “teaching by firsthand experience” isn’t carried out nowadays because horseplay has no place in the workplace, especially with electrical work.

A Little Engineering Theory

As previously mentioned, the voltage from the megohmmeter is quite high, but the current is significantly limited by its design and capacity. However, what happens when you’re ‘meggering’ large motor windings, long lengths of significantly sized diameter cables, thick bus segments, or other large objects with a substantial mass of metal that’s insulated or isolated from each other or from ground?

These floating ungrounded metallic objects essentially become large capacitors. A capacitor is nothing more than two metal parts separated by an insulator and is one reason why there’s a time delay for such massive metal parts to reach the intended test voltage levels.

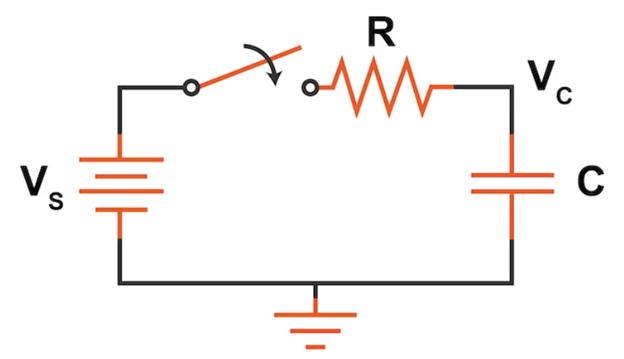

Since the megohmmeter is current limited by its fairly small output capacity, an amount of time is necessary for the object to reach full electrical test potential, i.e., the time needed to “fully charge the capacitor.” This is known as the “RC Time Constant” which can be calculated by the equation: Τ = R x C

Where Τ = time in seconds, R = resistance, and C = capacitance

The following diagram shows the basic components of an RC circuit, with VS as the voltage source (megohmmeter) and VC as the voltage of the capacitor (cable, bus, windings, etc.).

Since I’m not an engineer and this article isn’t an electrical engineering publication, we’ll end the electrical theory and continue with electrical safety.

Electrical Safety

Once the metallic object (conductor, bus, windings, etc.) is fully charged, it will have stored a significant amount of electrical energy across the two conductive parts (between the conductors or between a conductor and whatever’s grounded). That energy can reach dangerous levels which will be instantaneously discharged if accidentally touched by a worker.

In Part 2, I’ll share a recent event where an electrician suffered a nasty shock while performing electric insulation testing and some of the learnings from the accident which can help you prevent a similar accident in your workplace.

Excellent article George. I am 75 years old and it will always be “meggering the circuit” to me. LOL. I still have a 500 volt hand crank megger made by Megger Corp. and a Simpson 260 in my personal inventory. As you correctly stated it takes time to charge up the circuit but when the cranking stops and you touch the charged circuit it discharges almost instantaneously and you receive quite a jolt. Thanks for writing this.

Thanks for the nice words Bill. It means a lot to have one of the “Great Grandfathers” of electrical safety chime in with a encouraging note.

I have used a hand cranked megger in decades but more importantly, I also haven’t been on the receiving end of one for longer than that.

Take care Bill.