Risk Assessment

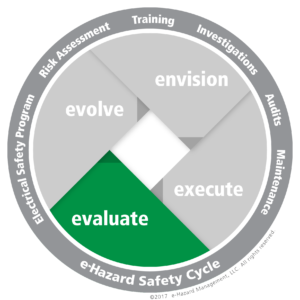

The e-Hazard Safety Cycle™

The e-Hazard Safety Cycle™ requires a firm basis and understanding of the risk assessment process. A good starting point would be the organization’s existing risk assessment system. We have found that using an existing system harnesses the power of familiarity. If the company does not have a risk assessment system, it should consider adopting a standardized system. Typical systems may include a quantitative risk assessment (scoring based on the frequency of the exposure, probability and consequence if the risk materialized) or BowTie risk assessments. See NFPA 70E®-2015 Annex F on the Risk Assessment Procedure.

Driving the concept of parallel processes is key to the e-Hazard Safety Cycle™. While the organization may be busy initiating a risk assessment program, there are two common hazards that have already been identified through consensus standards: arc flash and shock hazards. These are risk assessed through an arc flash engineering study that will include a shock assessment.

Following is an in-depth look at the risk assessment element using the “Envision, Execute, Evaluate and Evolve” cycle.

Envision: Identify Resources Needed for Electrical Hazards Risk Assessment

1. Define one person who will be responsible for the program. Ensure that a diverse mix of skills is included in the process. An engineering manager, engineer, and electrician may suffice for most organizations.

Resource planning:

- a. People – at a minimum, the program should include a manager, electrician, and an engineer.

- b. Oneline drawings, information on electrical equipment, labels on electrical equipment

- c. Software for the engineering study and an industrial printer and label stock.

2. It is recommended that the end goal be set, but the date for the end goal not be specified at this stage. Instead, focus on providing dates that the resources will be secured. If you need to buy software or hire a consultant, approval processes and budgeting may be factors outside of the program manager’s control.

3. If all approval and organizational support is in place, the arc flash engineering study and shock risk assessment may begin.

4. Once the study is completed, consider getting an independent review of the study before finalizing labels. This can be done by a engineer or an electrician.

Execute: Determine and Implement Mitigation Strategies for Shock and Arc Flash

1. Engage in awareness of the arc flash engineering study and the electrical shock risk assessment. Safety meetings attended by management are a good forum to pitch this program. Try to include facts – such as cost of arc flash or shock, pre-mitigation and post-mitigation risk numbers, the labelling of equipment, and engineering controls – to prevent unauthorized changes to protection settings.

2. At this stage, make the program immune to “people-changes”. That is, if any person has to be reassigned or leaves the company, the program should be robust enough to continue unabated.¹

3. Roll out labelling to address specific aspects of the arc flash and shock risk assessments. Labels should define the following (at minimum):

- a. The system voltage

- b. The arc flash protection boundary and shock boundary

- c. The arc rated protective gear

- e. Protective gear used against shock

Evaluate : Evaluate Mitigation Methods for Effectiveness

1. Observe whether the intended mitigation has materialized. This can be done through job observations, interviews or random audits. The number of near miss (near hit) incidents should have decreased.²

2. Also observe that the correct protective gear is used for the correct hazard exposure.

3. Observe for any changes to the electrical system that may warrant a revision of the arc flash study.

Evolve: Update Shock and Arc Flash Mitigation

1. When deviations are observed through the checking process, define one person who will be responsible to address those. Bear in mind that identifying a problem does not automatically propose a solution. At this stage, engage with the electricians in proposing remedial actions.

2. At this stage, your company’s Electrical Safety Program should be running autonomously to identify when protection settings or operating configurations change, electrical equipment is added/removed, and when the consensus five-year review is due.

In future literature pertaining to the RA in the e-Hazard Safety Cycle™, further discussion on the arc flash and shock assessment will be discussed.

¹See the “Electrical Safety Program” element for more guidance.

²See the “Incident Investigation” element for more guidance.

Ready to Get Started?

Join thousands of happy customers who have used our services.